Radon Solutions of CT Services

Radon testing and radon remediation to protect you from the colorless, odorless, radioactive gas known to cause lung cancer.

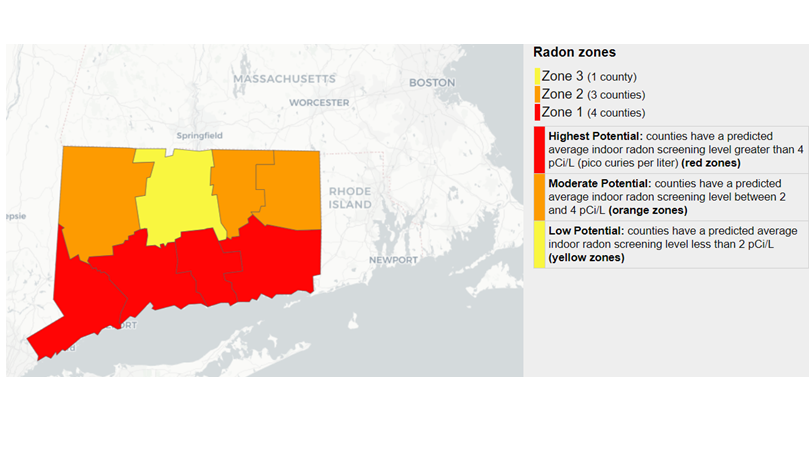

Radon is a colorless, odorless, radioactive gas that is the second leading cause of lung cancer, responsible for approximately 21,000 deaths per year in the U.S., more than all the fatalities caused by drunk driving. Radon in homes is a serious concern—many areas of Connecticut have high levels of radon in the air and water (see the map below).

Connecticut’s recommended radon mitigation level is 4.0 pCi/L for radon in air, and 5,000 pCi/L for radon in water. These are Connecticut’s threshold levels for radon mitigation. One should always strive for the lowest possible radon levels in air and water.

Radon Solutions of CT is Water-Flo’s radon division. We are certified to perform radon testing and to install radon mitigation systems for both radon in air and radon in water. We do this for concerned homeowners and businesses, and as part of the home inspection process for real estate transactions.

We Provide Radon Services Throughout CT

EPA Map of Radon Zones

It is recommended to test for radon:

- Every 5 years after a below threshold finding

- Every 2 years after a mitigation system is installed

- When you change the use of your home, such as finishing the basement or begin using a lower level as living space.

- If you are buying or selling the home

When dealing with radon, you should only hire a certified radon testing and radon mitigation professional. The national certification we hold must be maintained with continuing education and biennial testing. You can find the list of Nationally Certified Radon Mitigation Professionals on the Connecticut Department of Public Health website. Water-Flo/ Radon Solutions of CT are also nationally recognized by the American Association of Radon Scientists and Technologists (AARST).

Frequently Asked Question About Radon in CT

Radon in Water

Radon in water primarily originates from the decay of uranium, which naturally occurs in rocks and soil. Radon gas can dissolve into groundwater and be released into the air when water is used for drinking, cooking, showering, or other household activities.

Radon in water is harmful when aerated. Some studies show ingesting can lead to stomach cancer. The biggest concern comes when water is aerated at the faucet or in small confined areas which can increase the radon in air levels.

Testing for radon in water involves collecting water samples and analyzing them for radon concentration. Testing is typically conducted by certified laboratories using specialized equipment.

- State of Connecticut guidelines for radon in drinking water is 5,000 picocuries.

- It’s essential to be aware of any applicable regulations or guidelines in your area and take appropriate measures to address radon in water if necessary.

- If radon levels in water are found to be elevated, various mitigation options are available to reduce radon exposure. Common mitigation techniques include aeration, granular activated carbon filtration, and point-of-entry aeration systems.

- Homeowners should consult with radon mitigation professionals to determine the most effective and appropriate mitigation strategy for their specific situation.

When testing for radon in indoor air, it may be beneficial to also test for radon in water, especially in areas known for elevated radon levels in groundwater. Combining testing efforts can provide a more comprehensive assessment of radon exposure risks.

Types of Radon Mitigation Practices used in Connecticut:

- This is the most common method used for radon mitigation.

- It involves creating a suction point beneath the building’s foundation to draw radon gas away from the soil and prevent it from entering the building.

- A fan is installed to create negative pressure, effectively venting radon gas to the outside above windows and commonly above the roofline.

- A proactive approach to radon mitigation involves sealing cracks, gaps, and other openings in the building’s foundation, walls, and floors.

- By preventing radon entry points, this method can complement other mitigation techniques and help reduce radon infiltration.

- While primarily used for improving indoor air quality and energy efficiency, HRV or ERV systems can also help mitigate radon.

- These systems exchange indoor and outdoor air while retaining heat or coolness, reducing radon levels by diluting indoor air with fresh outdoor air.

- Positive pressurization systems introduce filtered outdoor air into the building, creating positive pressure that prevents radon infiltration.

- This method is more suitable for buildings with high radon levels and insufficient ventilation.

Radon Ready New Construction:

By integrating radon-resistant features into new construction projects, builders can proactively address radon risks and create healthier indoor environments for future occupants. This approach underscores the importance of considering radon mitigation from the initial stages of building design and construction.

Our Radon team has over 30 years of combined expertise in Mitigating, we stay up to date with new codes, continuing education and new technologies to give our customers the best experience possible!

- RRNC involves incorporating specific building techniques and materials during the construction phase to prevent radon infiltration.

- These measures are designed to create a barrier between the soil and the indoor living spaces, thereby reducing the potential for radon to enter the building.

- Gas-Permeable Layer: A layer of aggregate, such as gravel or crushed stone, is installed beneath the building’s foundation. This layer allows radon gas to move freely beneath the structure.

- Vapor Barrier: A thick, durable plastic sheet is placed over the gas-permeable layer to prevent soil gases, including radon, from seeping into the building.

- Ventilation Pipe: PVC pipes or similar materials are installed vertically through the building from the gas-permeable layer to the roof. These pipes allow for the passive venting of radon gas to the exterior of the building.

- Sealing and Caulking: Cracks, gaps, and other potential entry points in the foundation and walls are sealed to further minimize radon infiltration.

- RRNC typically includes passive radon mitigation systems, which rely on natural airflow and pressure differentials to vent radon gas.

- However, active components, such as a fan, can be added to enhance ventilation and further reduce radon levels if necessary.

- Positive pressurization systems introduce filtered outdoor air into the building, creating positive pressure that prevents radon infiltration.

- This method is more suitable for buildings with high radon levels and insufficient ventilation.

- Incorporating radon-resistant features during construction adds relatively minimal cost compared to retrofitting existing buildings.

- RRNC not only reduces the risk of radon exposure for occupants but also enhances the overall indoor air quality and comfort of the building.

- Architects, builders, and contractors play crucial roles in implementing RRNC techniques effectively.

- Consulting with radon mitigation experts during the design and construction phases can ensure that the building meets or exceeds radon-resistant construction standards.

Schools, Commercial Buildings, and Multifamily Homes:

Testing is required by the State of CT every 5 years in schools

Schools are required To Submit “Radon Re-Evaluation Report Form”

Sub Slab Depression is common, as well as using HVAC ductwork to balance and pressurize areas where levels are high

Commercial buildings can have a severe “Stack Effect” that can pull radon gases multiple stories upward.

Multizone HVAC equipment can play a large role in controlling Radon levels in large spaces

Radon systems can also be used as VOC gas control systems in Commerical applications

Multifamily testing in Connecticut is not largely regulated but EPA/NRPP recommend testing every 3 years.

Sub Slab depressurization is most common method in multifamily homes

If living behind ground level you should most definitely test your living space